New Technologies

NT in NT K+D AG stands for new technologies, it has always been a focus of ours to find, test and then offer the newest production methods for the benefit our clients. 3D printing which has its strengths in versatility, innovation and prototype manufacturing was hence identified as a possible key technology for us. We started with additive manufacturing as a first production method in 2013 and have since vastly broadened our know-how in time intensive testing. Since 2016 we now offer our 3D printing service as a welcomed addition to our other offers.

Thanks to our experienced team we are able to offer you a seamless and hassle-free 3D print service.

This includes helping you to find the right printing method and materials, constructing models on PC, or scanning real world models.

We offer a wide range of services including additive printing such as FDM, SLA, SLS, MJF and Polyjet , subtractive 3d printing, machining, or also injection moulding. Just contact us and we will do our best to find a solution that fits your needs.

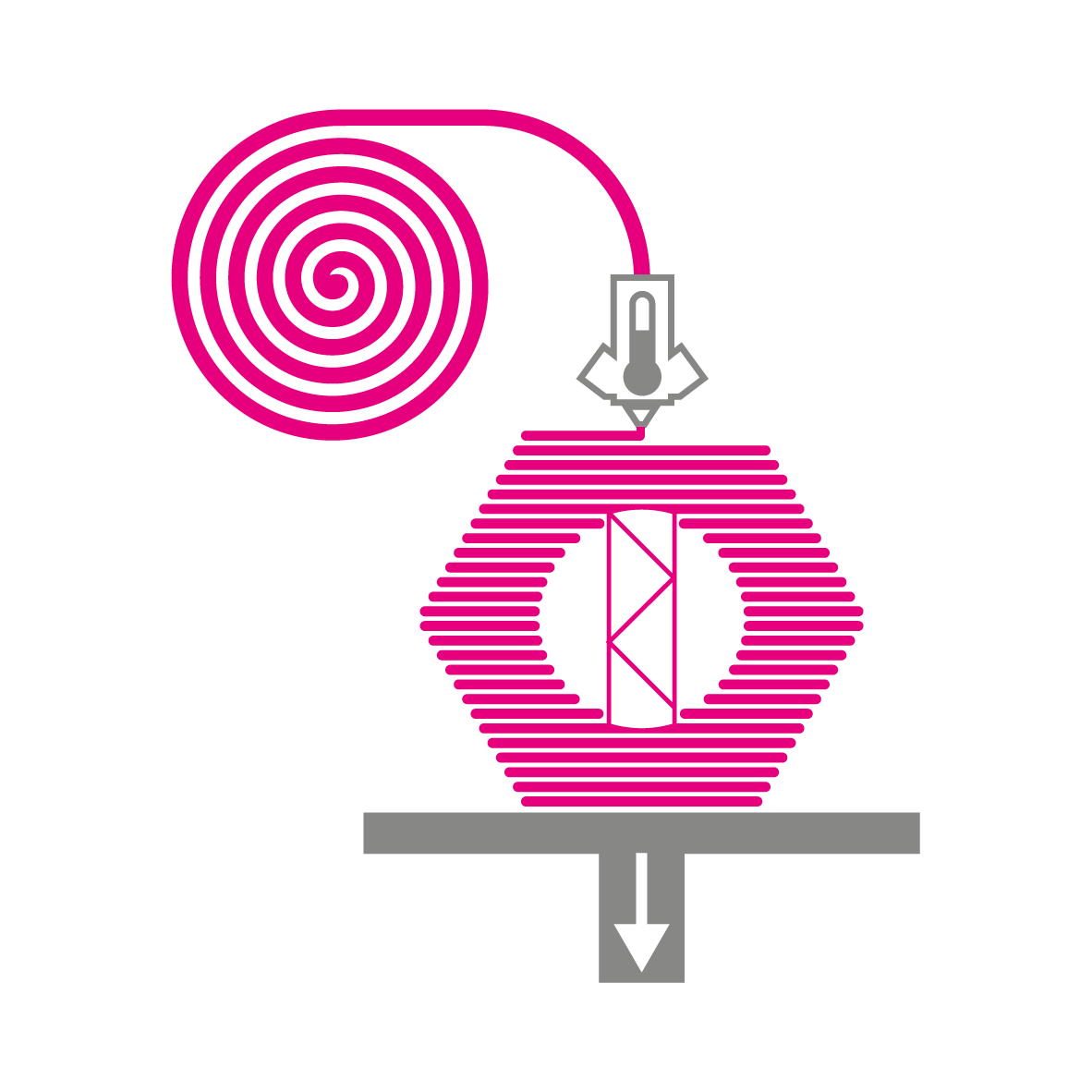

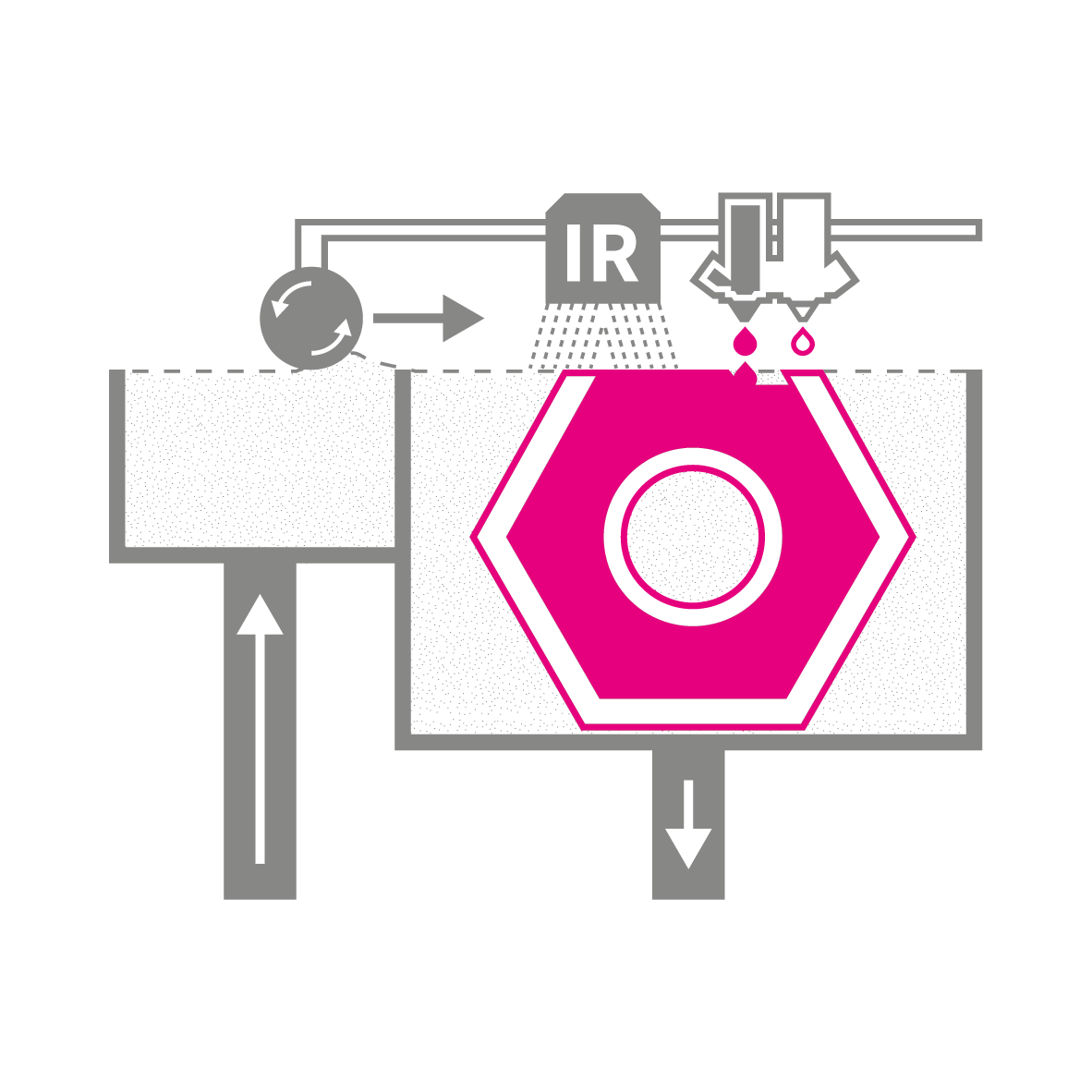

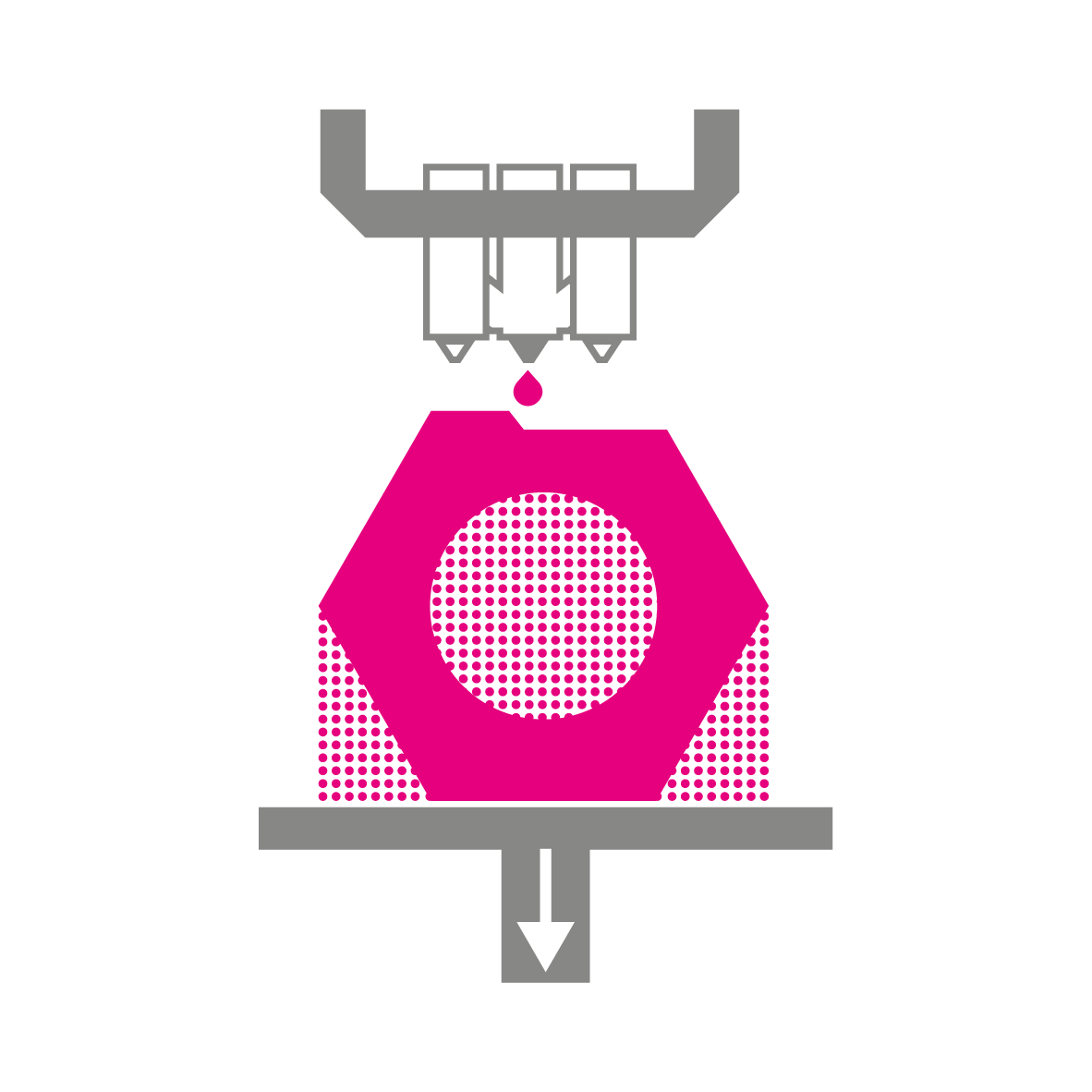

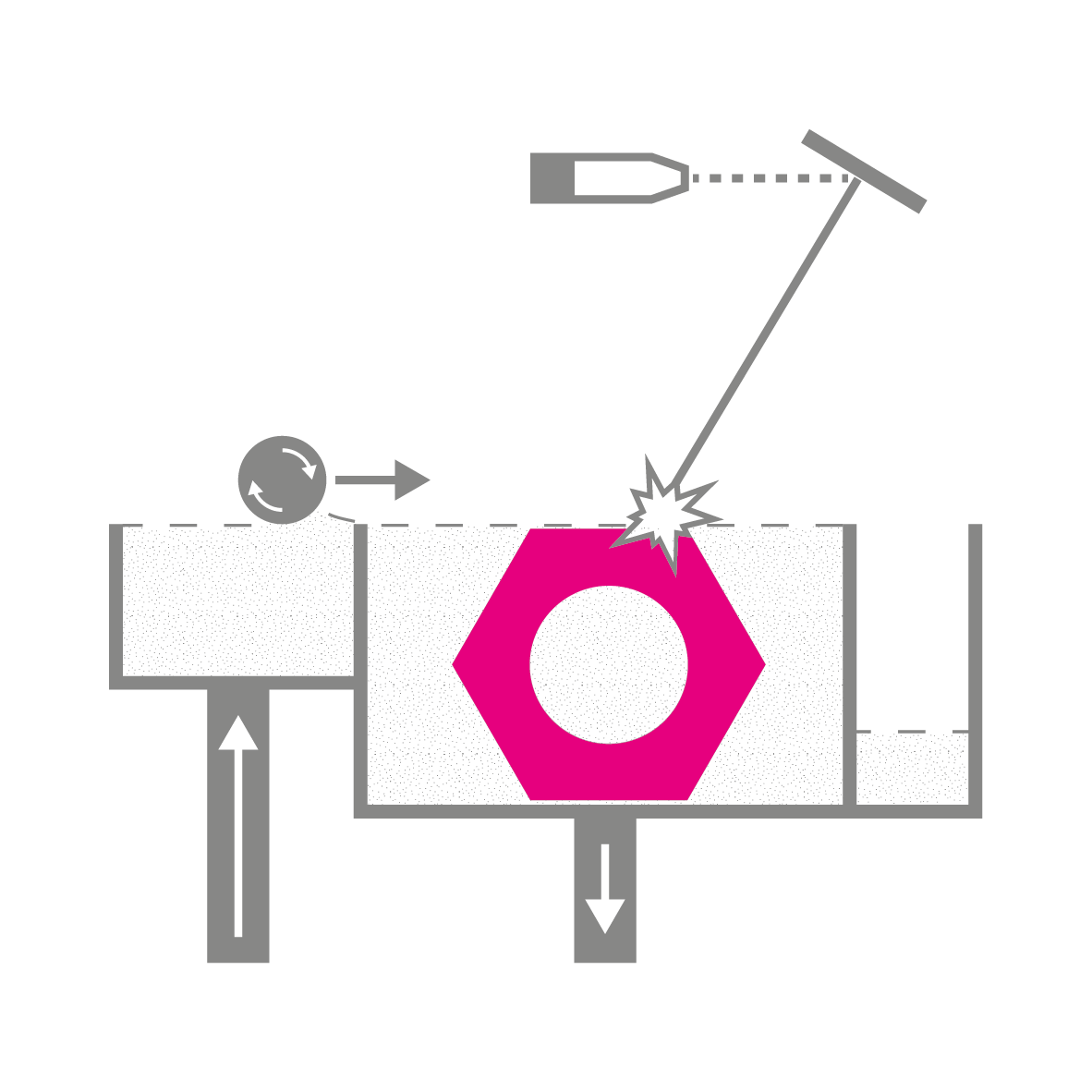

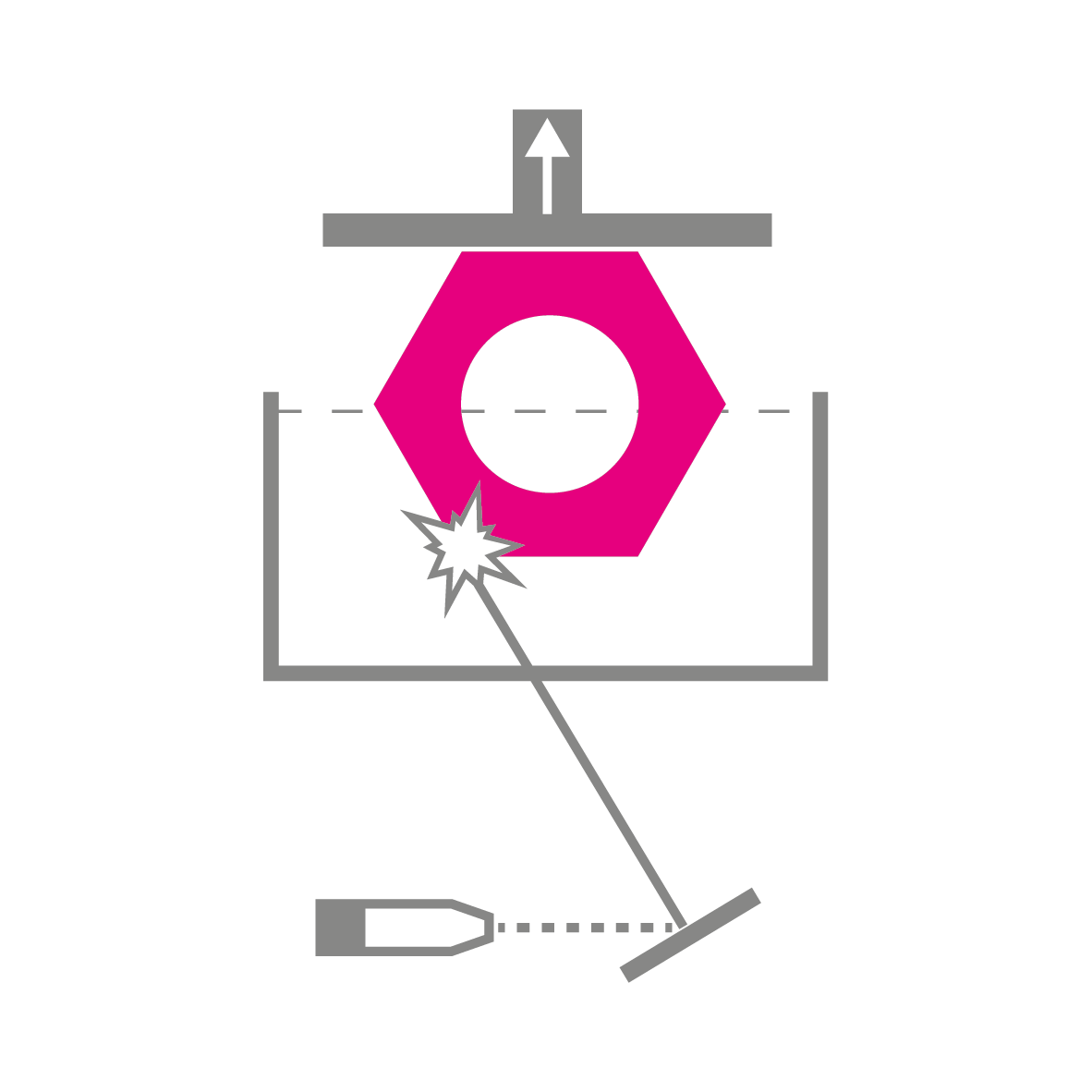

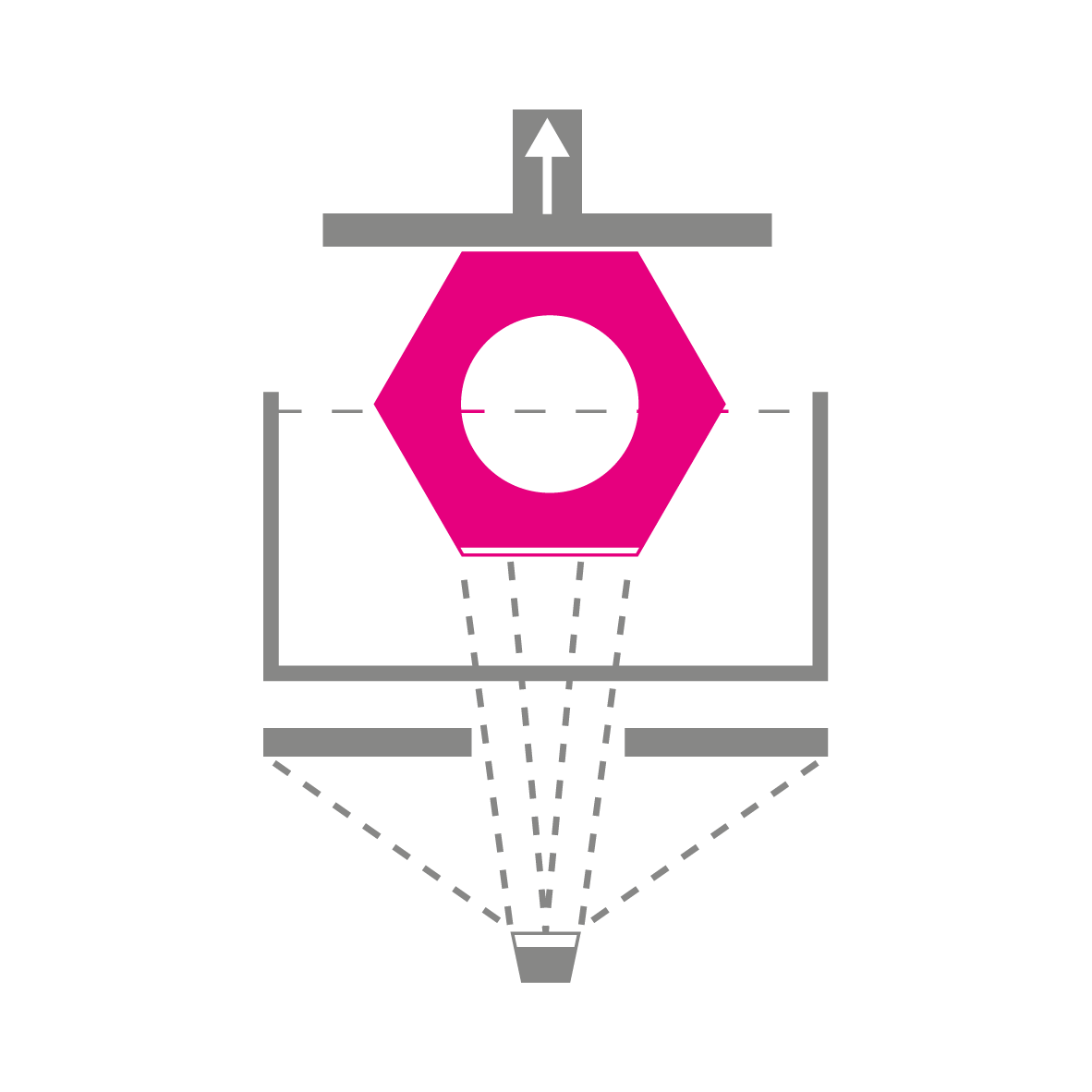

Our additive printing methods and their pros and cons

Each 3D printing method has its advantages and disadvantages, to give you a better oversight we created a short guide and pictograms to visualise each process.

If you would like more information or individualised advice please contact us by phone or e-mail and we will gladly consult you to find the best solution for your project.

Advantages

- Allows the utilisation of classical plastics.

- 3D printing speed of 100m/min possible.

- Cost-effective.

Disadvantages

- Overhanging/protruding structures will need support structures.

- Extremely small structures might not be possible.

Advantages

- Produces smooth and detailed prototypes which can visualise the wished for appearance of the final product.

- Allows the production of precise moulding tools, forming tools, and assembly-jigs.

- Is able to create complex forms, elaborate details and fine textures..

- Can integrate multiple materials and colours in one single model.

Disadvantages

- The materials do currently not resist temperatures higher then +55°.

- Higher cost segment.

Advantages

- Small structures can be produced with precise measurements.

- Freedom in design as no support structures are needed.

- Clean surfaces .

- High structural strength.

- Allows utilisation of classic plastics and thermoplastic elastomers in poweder form.

Disadvantages

- Printers and the procedure itself are costly.

- Slow printing process.

Advantages

- Small structures can be produced with precise measurements..

- Freedom in design as no support structures are needed.

- Clean and neat surfaces.

- High structural strength.

- Allows utilisation of classic plastics and thermoplastic elastomers in powder form.

Disadvantages

- Printers and the procedure itself are costly.

- Slow printing process.

Advantages

- Small structures can be produced with precise measurements.

- Extra clean and smooth surfaces.

- Better resolution detail than FDM and DLP.

Disadvantages

- Overhanging/protruding structures will need support structures.

- Slower print speed than FDM print.

- Higher costs as UV-Resins are more expensive.

- Slower printspeed than DLP method as resin is hardened selectively rather then layer by layer.

Advantages

- Small structures can be produced with precise measurments.

- Extra clean and smooth surfaces.

- Higher print speed than SLA due to layer by layer hardening.

- Better resolution detail than FDM.

Disadvantages

- Overhanging/protruding structures will need support structures.

- Slower print speed than FDM method.

- Higher costs as UV-Resins are more expensive.

We have the right tools and expertise to turn your 3D project into reality, contact us now.