Back-up rings and guiding elements do not have a sealing function, but they are essential for the longevity of other components.

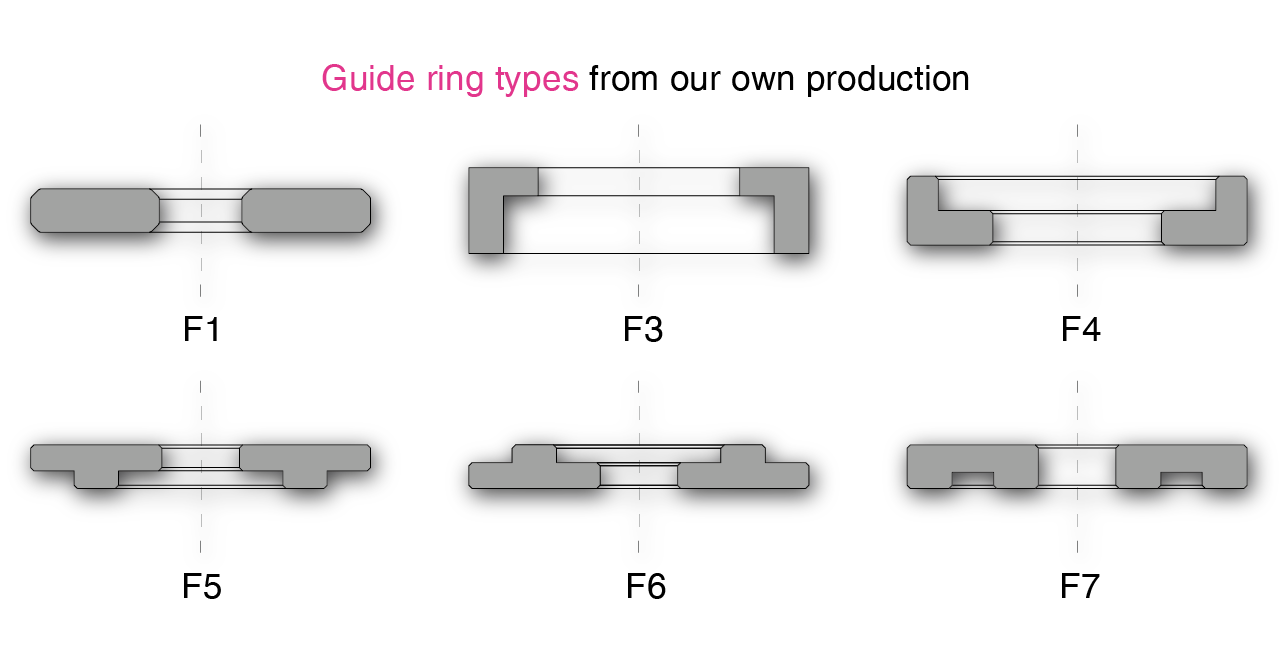

Guiding elements such as guide rings and guide bands absorb the lateral forces as they guide the components into each other without direct contact thus protecting them. With this added layer of protection they significantly improve the performance of the sealing system.

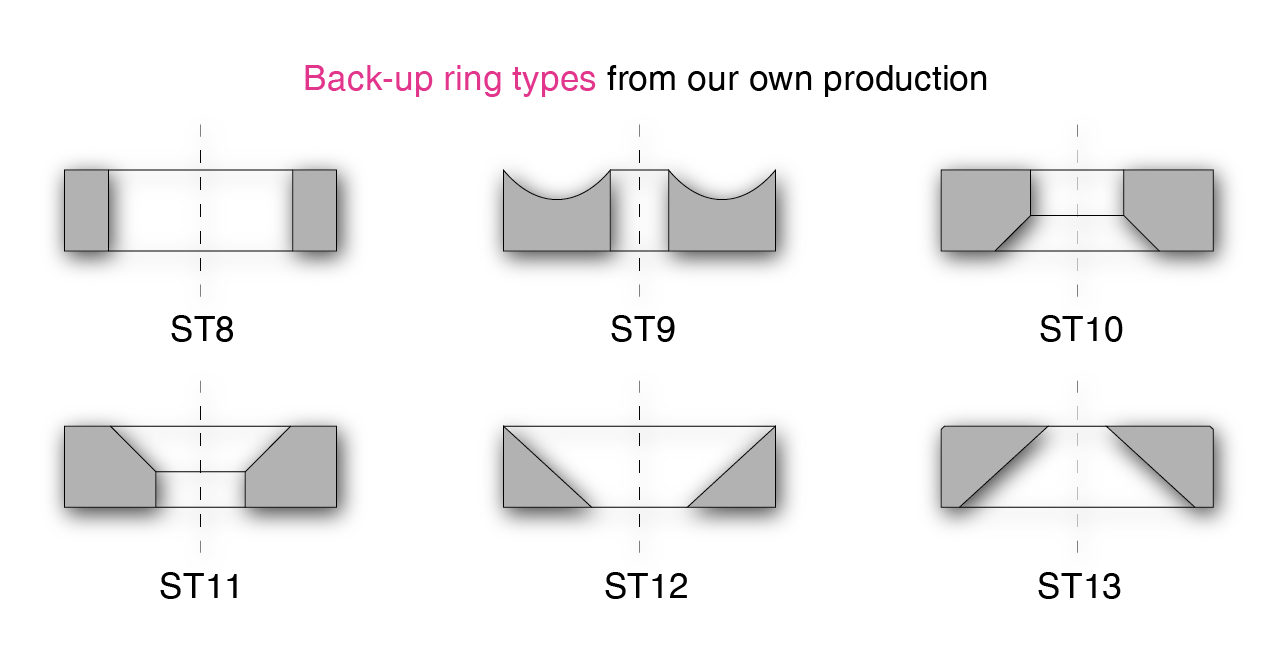

Back-up rings on the other hand protect O- or X-rings from gap extrusion at higher pressures.

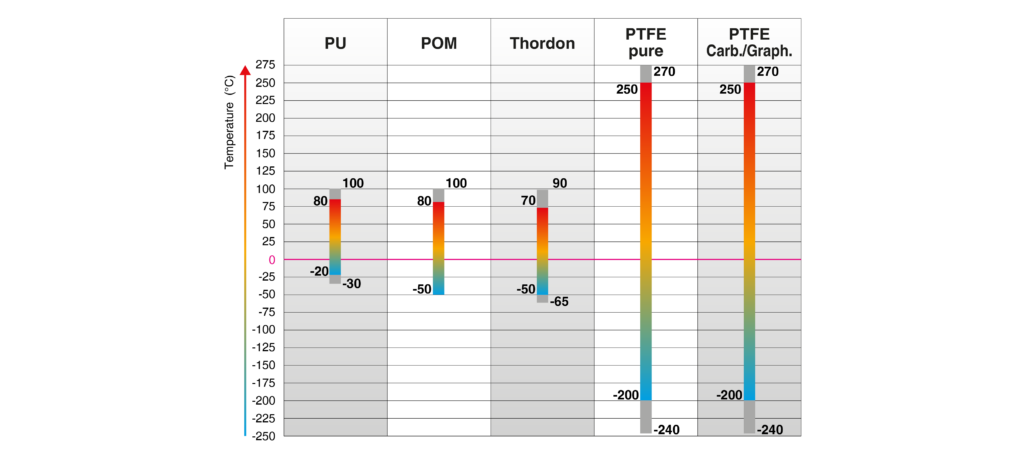

Operating temperatures

Materialguide

Advantages

- Pressure resistant to over 400 bar.

- Hydrolysis resistant.

Disadvantages

- Poorly suited for steam applications.

Advantages

- Good mineral and bio-oil resistance.

- Suitable for applications with alcohol and water up to 90℃

Disadvantages

- Not suitable for applications with steam, air over 100℃ and ozone.

Advantages

- Perfectly suited for abrasive and harsh environments.

- Wear resistant.

Disadvantages

- Low thermal resistances.

- Water absorption.

Advantages

- High chemical resistance.

- Usable for many applications in pharmaceutical and food industries.

- FDA approved.

Disadvantages

- Prone to cold flow/creep.

Advantages

- High chemical resistance.

- Usable for many applications in pharmaceutical and food industries.

- Good thermal conductivity

Disadvantages

- Abrasion particles can be visible as the material is anthracite coloured.