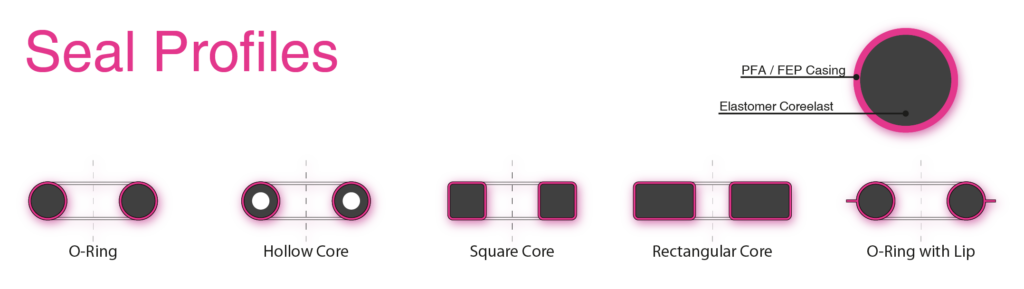

Encapsulated o-rings are used when the chemical resistance of elastomers is no longer sufficient. The FEP, PFA or PTFE coating can then be used to protect the core from damages while still retaining elasticity.

Seamless encapsulated o-rings can be installed in the same grooves as the elastomer counterparts.

Encapsulated o-rings are hence used universally and achieve long service lives in applications with harsh chemical enviroments.

These state of the art sealing elements are ideal for sealing corrosive and hot gaseous, liquid or solid substances in chemical, biomedical, paper, food, electronics, electroplating, water treatment and many other industries.

Typical applications for encapsulated o-rings are pumps, armatures, centrifuges, mechanical seals and many more.

Flat gaskets can also be encapsulated with PTFE, PFA or FEP without any problems.

PTFE Encapsulated O-Rings

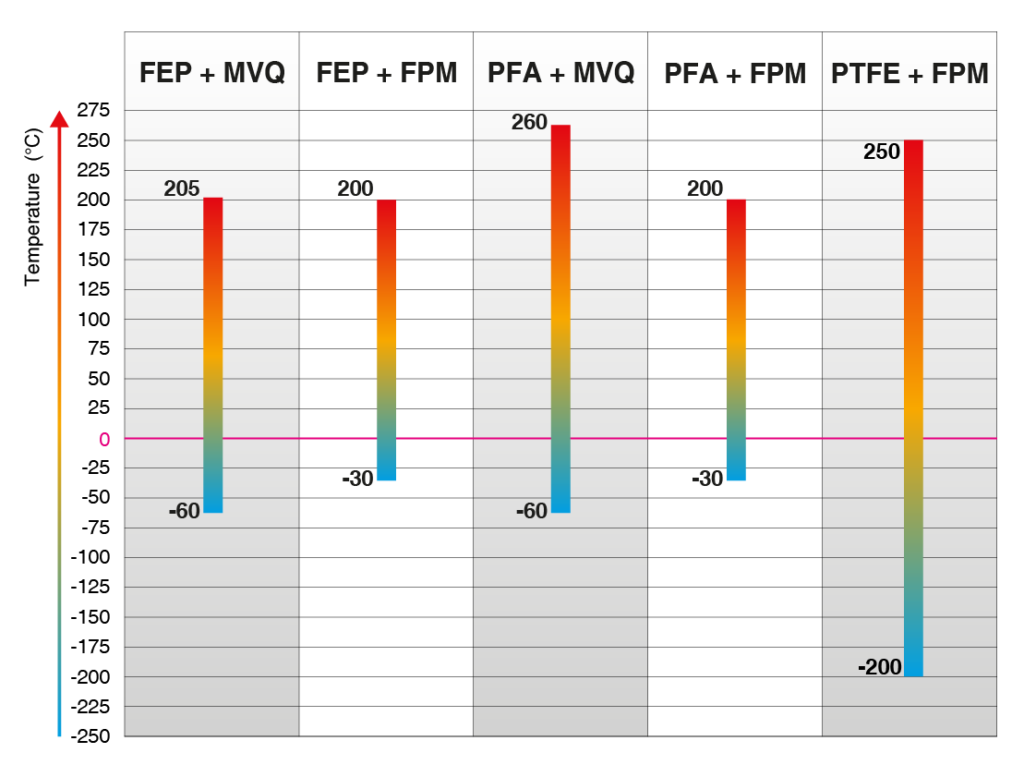

The PTFE cover gives the O-ring a significant tensile strength, elongation and kink resistance as well as a low coefficient of friction. In addition, the temperature range is massively extended. The PTFE cover therefore enables a clear increase in properties compared to FEP or PFA-coated O-rings. It is particularly suitable for reuse problems or when a longer seal life is generally expected. An additional advantage is the FDA approval which is made possible by the PTFE material.

Operating Temperatures

Materialguide

Advantages:

- Excellent chemical resistance.

- High thermal resistance.

Disadvantages:

- Only suited for static applications.

Advantages:

- Excellent chemical resistance.

- High thermal resistance.

Disadvantages:

- Only suited for static applications.

- Low cold flexibility.

Advantages:

- Excellent chemical resistance.

- Excellent thermal resistance.

Disadvantages:

- Only suited for static applications.

Advantages:

- Excellent chemical resistance.

- High thermal resistance.

Disadvantages:

- Only suited for static applications.

- Low cold flexibility.

Advantages:

- Very good chemical resistance and can be used in the pharmaceutical and food industries without any problems

- FDA certified

Disadvantages:

- Only suited for static applications.

- Low cold flexibility.