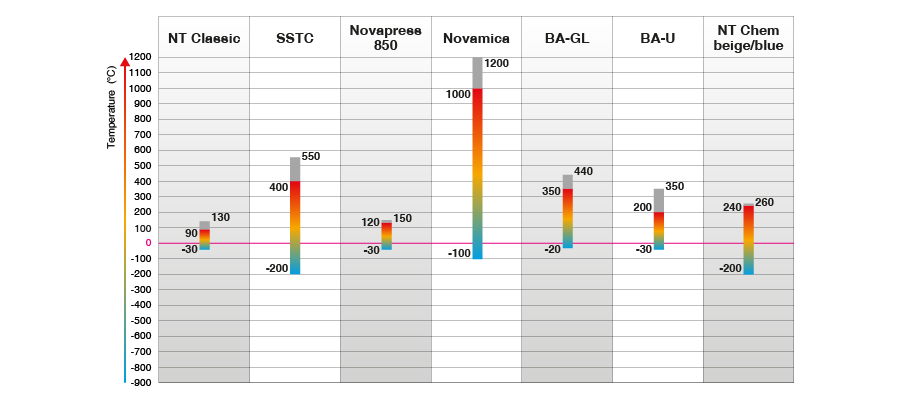

We have an extensive and modern range of gaskets which cover a wide span of applications. Our gaskets seal in the range of 0 to 13 pH and at temperatures from -250℃ upto +1000℃.

Standard gaskets are always in stock and we can also supply our materials individually on request. We are also able to directly manufacture your gaskets up to a diameter of over 10 metres.

With the growing range of specialised high-tech materials it can become difficult to get and keep an overview, but don`t worry. Just let us know your area of application and exact requirements and we will offer you the most advantageous solution.

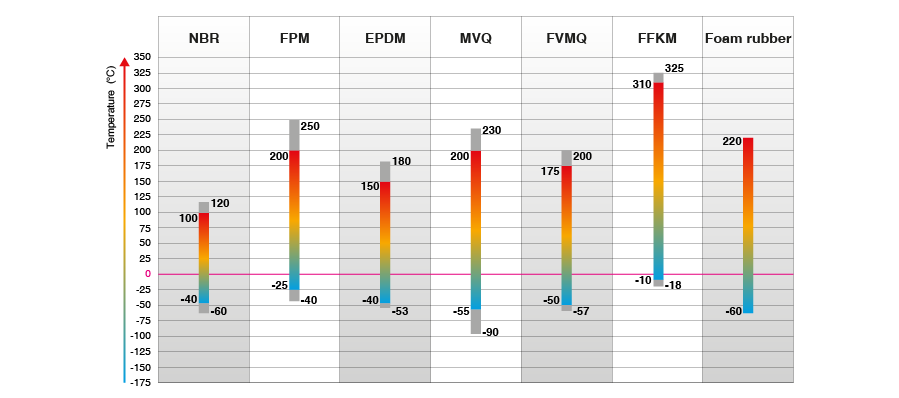

Operating temperatures

Material guide

Advantages:

- Universal sealing material.

- Physiologically harmless.

- Highly resistant to external influences.

Disadvantages:

- Limited chemical and thermal resistance.

Advantages:

- Excellent adaptability to uneven surfaces.

- Blow-out proof due to stainless steel mesh layer.

- Non-stick coating.

Disadvantages:

- Installation handling requires a high degree of attention. It is hence advised that the installation is carried out by a specialist.

Advantages:

- Excellent adaptability to uneven surfaces with minimal contact pressure.

- Exceptionally low leakage, even with weakly tightened screws.

Disadvantages:

- Limited thermal resistance.

Advantages:

- Sealing functionality at temperatures up to 1000℃.

- Manufacturing of small products in detail possible.

Disadvantages:

- Installation handling requires a high degree of attention. It is hence advised that the installation is carried out by a specialist.

Advantages:

- Good steam and heat resistance.

- Resistent to oils, gases, fuels and acids.

Disadvantages:

- Limited chemical resistance.

Advantages:

- Universal sealing material.

- Good mechanical and thermal properties.

Disadvantages:

- Limited chemical resistance.

Advantages:

- Excellent chemical resistance.

- Best resistance to cold flow/creep.

- Excellently adapts to flange unevenness and covers all common process conditions.

Disadvantages:

- Requires higher surface pressure than other gasket materials.

Advantages:

- Good swelling resistance to mineral oils, greases and diesel fuels.

Low gas diffusion.

Disadvantages:

- Insufficient weather and ozone resistance.

- Requires special protective agents

Advantages:

- Excellent resistance to chemicals and mineral oils.

- High heat resistance.

- Lowest permeability rates for most gases.

Disadvantages:

- Not resistant to polar solvents.

Advantages:

- High resistance to ozone, heat, hot water and alkaline and acidic solutions.

- Resistant to polar solvents.

Disadvantages:

- Not mineral oil resistant.

Advantages:

- Excellent thermal resistances.

- Excellent ozone resistance.

- High electrical resistance.

Disadvantages:

- Low resistance to gas diffusion.

- Average mechanical properties.

Advantages:

- Higher swelling resistance to fuels, mineral oils and synthetic oils than MVQ.

- Suitable for even higher temperature ranges.

Disadvantages:

- Low resistance to gas diffusion.

- Average mechanical properties.

Advantages:

- Highest heat and chemical resistance.

Disadvantages:

- Low resistance to cold temperatures.

Advantages:

- Very high adaptability.

- Excellent thermal resistances.

- Excellent ozone resistance.

- High electrical resistance.

Disadvantages:

- Low resistance to gas diffusion.

- Average mechanical properties.

Did you know?

Not only are we able to manufacture any custom gasket in the mentioned materials, we can also produce oversized gaskets with dimensions of over 10 meters for you.

Gaskets which reach these dimensions are manufactured in several segments depending on the requirements and joined together during assembly.