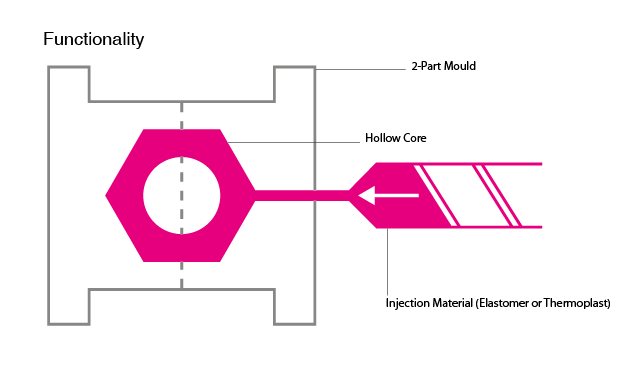

Injection moulding is the process of injecting an elastomer (rubber) or thermoplastic into a mould. This process is suitable for batches of 500 or more pieces and can also be a solution for products which have to be made of an elastomer which is softer than 85 Shore A which is often problematic for other processing methods.

Most People are well aware of the rather high price tag that comes with the production of moulds, luckily this is however not always the case, and we will gladly quote you your specific solution.

Our prices in the prototype area start at an affordable 250.- CHF, while the conventional injection moulds start from around 600.- CHF per mould.

Delivery times for injection moulds can often take up to 15 weeks. As an alternative to bridge these waiting times, we offer to manufacture your otherwise injection moulded products as a 3D printed version. Series of several 1000 Pieces can easily be produced within a week this way. An additional benefit is the possibility to print these pieces in the same material they would have been moulded in. This allows to directly test the functional capabilities of a new product and can help you avoid long wait times and expenses that would arise from mould changes.

Through our accumulated experience and worldwide network of suppliers we can guarantee to meet your requirements from favourable prices to highly precise individual specifications.

NT K+D AG will also supply you with all the required certificates for your project.

Conventional Injection Moulding

We produce rubber and plastic products from diverse materials for a wide range of applications. These include but are not limited to various forms of sealing strips, rubber stoppers, rubber pads, switches and for example housings. They are then used in the food, pharmaceutical sanitary and other production industries.

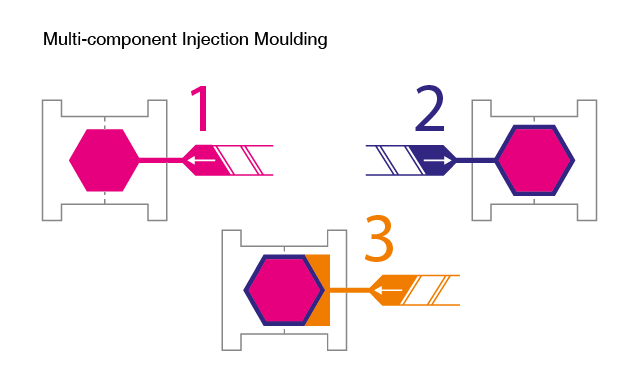

Multi-Component Injection Moulding

A toothbrush has soft bristles, a rubberised handle, and a hard plastic core. The production of such a seemingly simple article requires several steps. First the plastic material for the handle will be injected in the first mould, shortly after a second mould is fitted on the handle which now has room for the injection of the second material to rubberise it. To do this the plastic handle must however first be given a vulcanisation coating as the rubber injection would otherwise not bond with the handle. The second mould then allows a partial or full rubberization.

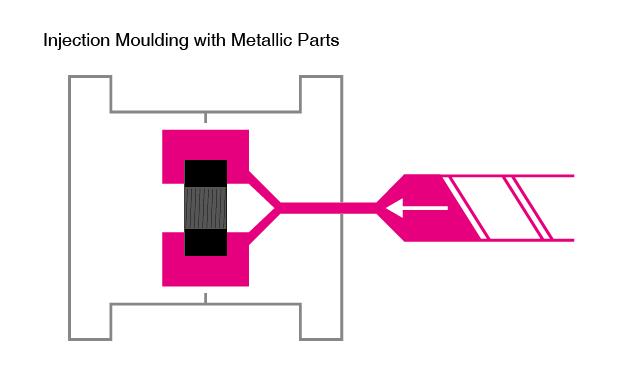

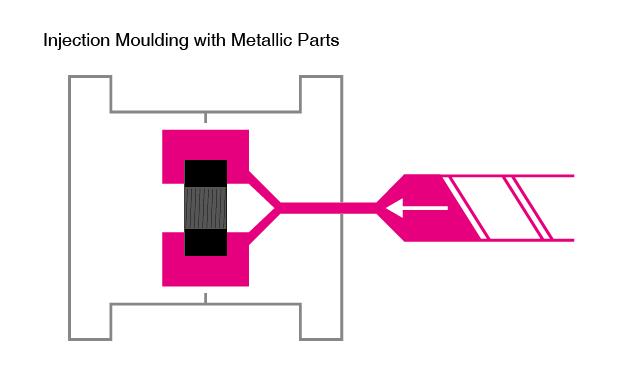

Plastic-Coated Metal Parts

In this process a metallic part can be augmented with plastic or an elastomer material. Just as in multi component injection moulding, the surface needs an appropriate coating which allows the metal and injected material to bond.

Most thermoplastic prototypes can be 3D printed to test the fit and suitability of the material and product. If the application however requires a quite soft material there are limitations on what 3D printing and milling can produce. In these cases the creation of a mould for injection moulding is often the preferred option as the resulting product is usually more stable than their 3D variant. This guarantees better function and more clarity on the suitability of the prototype.

This mould type is perfect for prototyping, as it can be realised very cost efficient. This is suitable for projects with dimensions of up to 600 x 600 x 1500 mm. The mould accuracy is +/- 0.2 mm for smaller objects and +/- 0.8 mm for larger ones. Next to FDM we also have PEEK or ULTEM moulds which are suitable for the processing of thermoplastics and elastomers on conventional injection moulding equipment.

These moulds are a true marvel of 3D printing and fulfil high qualitative demands. If you wish to hold your injection moulded prototype in your hands in just a weeks time and have a tolerance range of +/- 0.1 mm this might be the right product for you. Simply instruct your injection moulding supplier to get in touch with us and we can produce your mould and send it to their workshop within 3 days. The cost of these moulds is usually around 20 % of an aluminium or steel one and they can be used to produce up to, and more than 100 pieces of your prototype.

Internally, we process silicone in the hardness of 22 and 45 Sh A with food approval. On request we also process PU or other materials, let us know your specifications and we will gladly advise you.

PP, PA, POM, ABS, PEEK, HDPE, PE, PPSU, PPS, PS, LCP, PVC, PEI, PMMA, PES, PVDF, PFA, PI, PBI, PAI.

NBR, EPDM, PU, TPU, TPE, NR, TPC, TPV, MVQ, Silikon, FPM, CR, H-NBR, FFKM, in multiple colors and hardnesses.