In contrast to normal O-rings which are manufactured in one piece we also have the option to create seals from an extruded elastomer cord. This allows us to provide O-Rings in any diameter in a short time. The cord is simply cut to the required length and then glued or vulcanised at the ends. The only restrictions are the minimum diameter of the groove and the thickness of the cord that can be used.

There are however also some disadvantages to vulcanised or glued cord seals. They are not suitable for dynamic sealing applications and only partly suitable for use in conjunction with gases and vacuum applications. It is advisable to pay special attention to the glued or vulcanised joint.

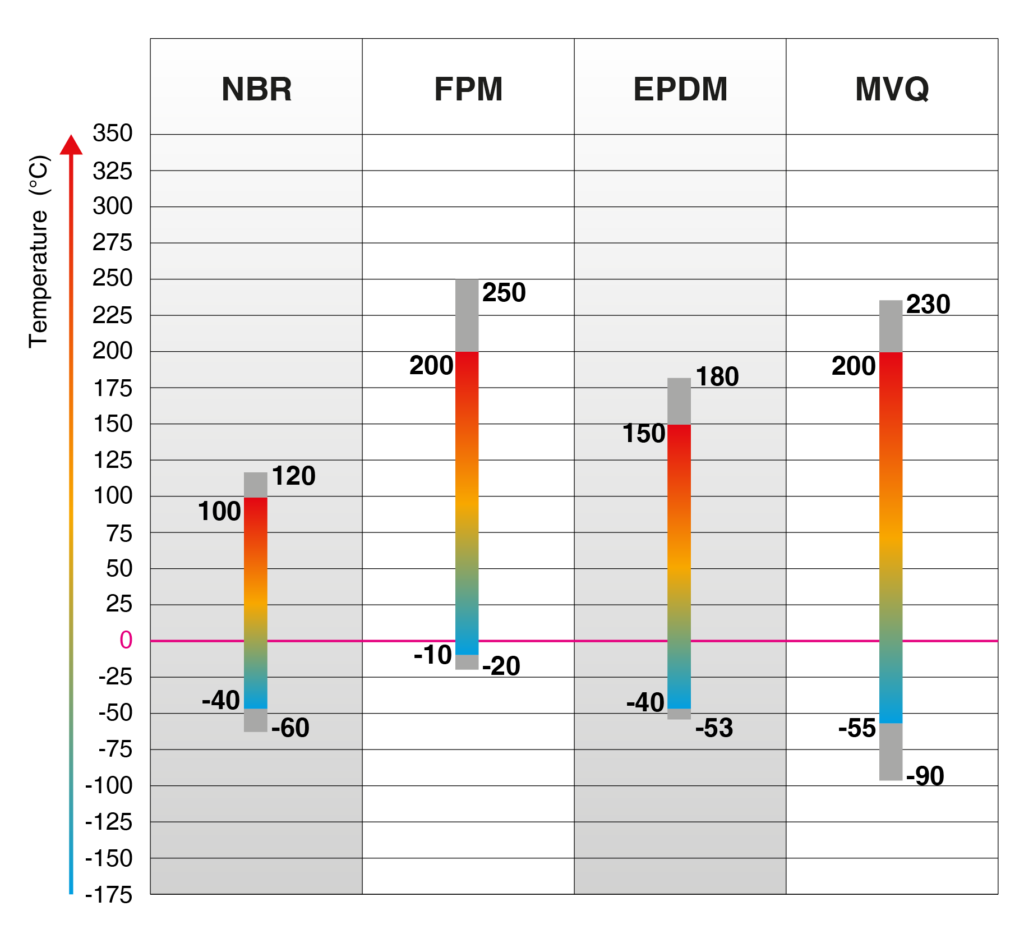

Temperature range

Compound guide

Advantages

- Good swelling resistance to mineral oils, greases and diesel fuels.

- Low gas diffusion

Disadvantages

- Insufficient weather and ozone resistance

- Requires special protective agents.

Advantages

- Excellent resistance to chemicals and mineral oils.

- High heat resistance.

- Lowest permeability rates for most gases.

Disadvantages

- Not resistant to polar solvents.

Advantages

- High resistance to ozone, heat, hot water and alkaline and acidic solutions.

- Resistant to polar solvents.

Disadvantages

- Not mineral oil resistant.

Advantages

- Excellent resistance to heat and cold.

- Excellent ozone resistance and high electrical resistance.

Disadvantages

- Low resistance to gas diffusion.

- Average mechanical properties.