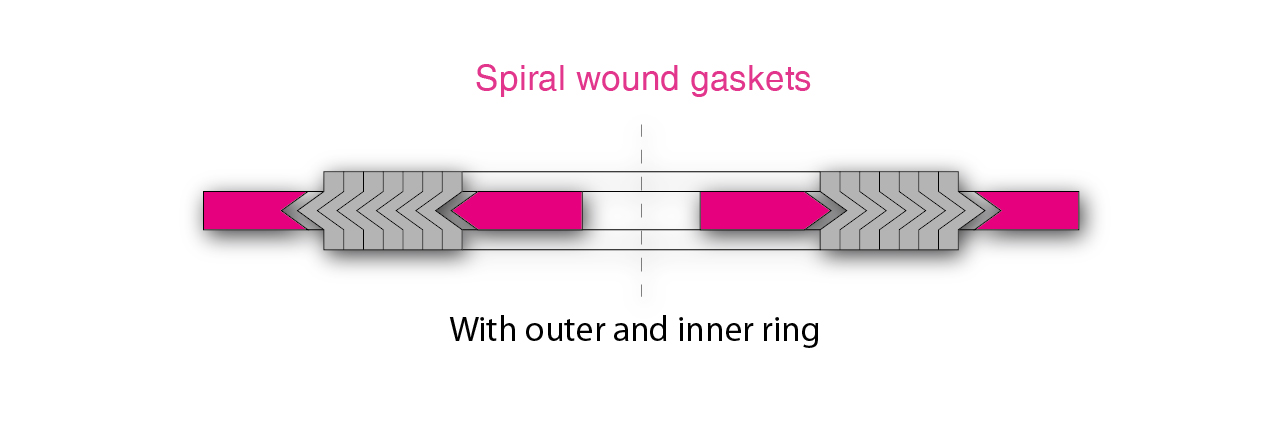

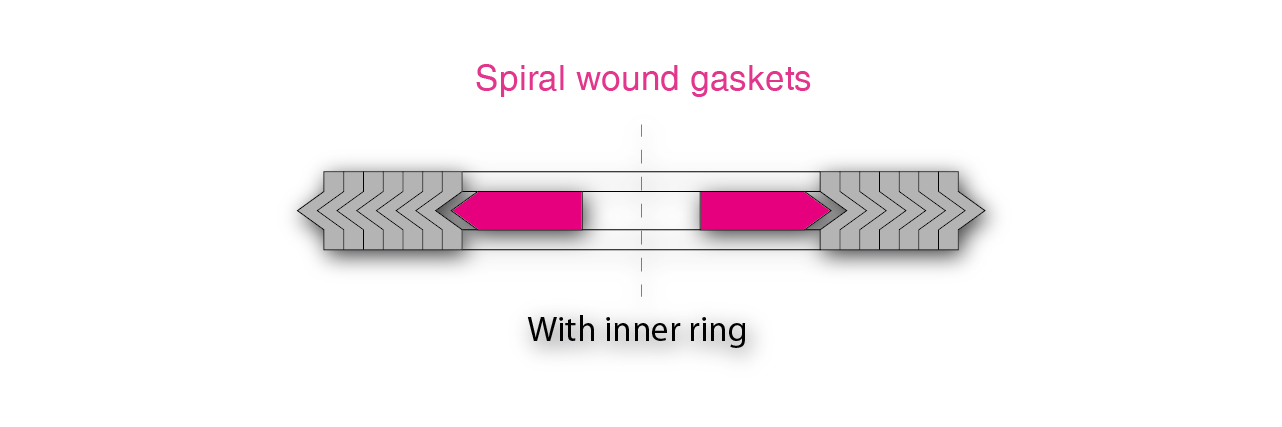

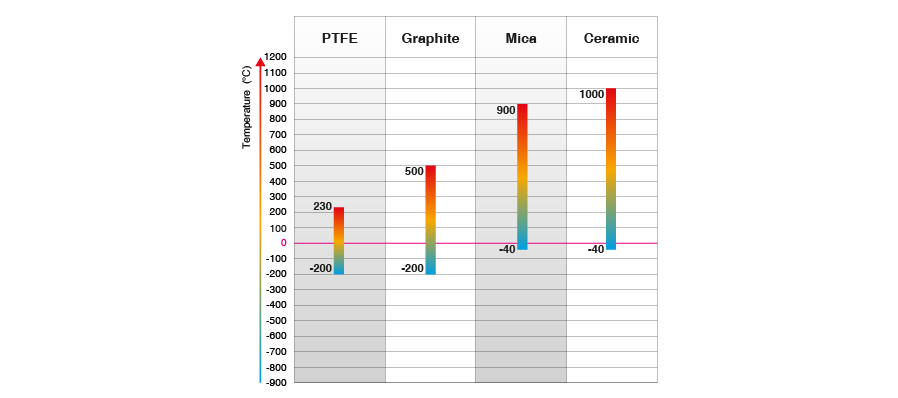

Spiral wound gaskets are used in challenging high pressure environments. They have proven to offer exceptional safety up to temperature limits of for example 1000°C with ceramic fillers and, depending on matierals, pressure limits of up to 320 bars.

The spring-back properties compensate for the component expansion differences associated with pressure and temperature fluctuations and prevent the resulting sealing gap. This guarantees a reliable sealing function under harsh conditions.

Gasket dimensions

Spiral gaskets for DIN and ASME flanges, special dimensions up to 3000 mm

Pressure range: PN 10 to PN 320, Class 150 to 2500

Gasket thickness: unpressed 4.5 mm (standard), pressed 3.4 mm. Other gasket thicknesses on request.

Center and inner ring: 3 mm (standard), other sizes on request.

Additional Shapes

Production of spiral-wound gaskets for heat exchangers or covers with an oval shape is possible

Operating temperatures

Material Guide

Advantages:

- High chemical resistance.

- Usable for many applications in the pharmaceutical and food industries.

- FDA approved.

Disadvantages:

Prone cold flow/creep.

Installation handling requires a high degree of attention. It is hence advised that the installation is carried out by a specialist.

Advantages

- High chemical resistance.

- High thermal resistance.

Disadvantages:

- Installation handling requires a high degree of attention. It is hence advised that the installation is carried out by a specialist.

Advantages:

- High resistance to heat.

- High chemical resistance.

Disadvantages:

- Installation handling requires a high degree of attention. It is hence advised that the installation is carried out by a specialist.

Advantages:

- Excellent heat resistance.

- Good chemical resistance.

Disadvantages:

- Installation handling requires a high degree of attention. It is hence advised that the installation is carried out by a specialist.