Creative & pragmatic solutions - We turn ideas into reality

With our extensive range of machinery we are able to use a wide variety of processing methods for your prototype development. This advantage allows us to offer you a result that fits your ideas and wishes.

We first discuss specifications and goals with you to then find a fitting solution and will create a CAD drawing which serves as a digital template. This enables us to produce a prototype which we can then test for you. After successful testing this prototype can be manufactured as an individual piece or in larger batches.

Depending on the situation, we use a combination of our diverse manufacturing options. These include 3D printing, machining techniques, injection moulding and more. We are aware of the fact that no prototype is alike and hence flexible in our advice and implementation.

Theme guide

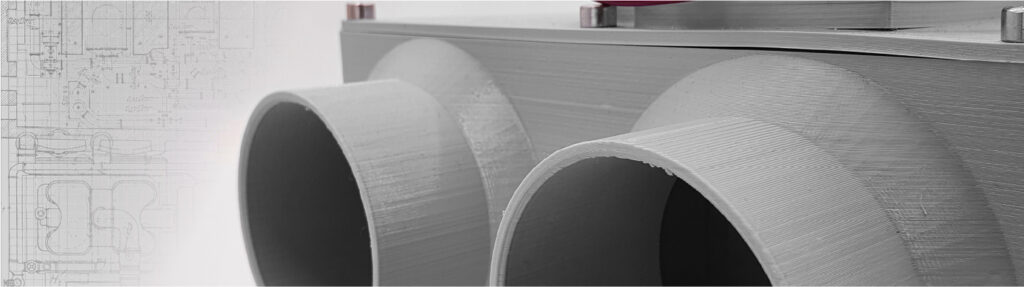

3D printing is your perfect companion for functional prototypes. Through performance tests, you can check the thermal, chemical and mechanical load capabilities of your model. You receive exact performance data and can thus convince with your product.

Our accurate models give you the opportunity to showcase product designs, inspect shaping and ergonomics as well as trialling assembly. This makes it possible to identify and fix design flaws in early stages of development.

Our range of materials covers elastomers, plastics, specialised compounds and more.

Our Materials.

We also manufacture non-standard seals according to your specifications and wishes.

PolyJet 3D printing technology allows us to produce exceptionally precise tooling templates with smooth surfaces and no need for post-processing. Being able to produce tools in small batches means you can manufacture prototypes with the same process and materials that you use for the final product.

We have the know-how and tools to directly manufacture bellows and moulds according to your specifications.

NTKD AG combines 3D printing and sealing technology to generate an advantage for our clients. This allows you to make early improvements, recognize and fix mistakes before costs are incurred and focus on marketing.

Our prototyping techniques range from cutting, stamping and machining to various types of 3D printing.

Our manufacturing technologies

We offer attractive project packages which provide you with concept development from just CHF 65/hour. This includes design, material selection and construction.

Our trained experts work with modern CAD programs to create drawings according to your specifications at an hourly rate of 80.- CHF.

On request, we also provide introduction courses which give you a deeper insight into the materials and processes we offer. This allows you to get to know their advantages, disadvantages, and possible applications.

If time is of the essence, it is possible to produce your prototype with our “Expedite Service”. If this is feasible for your prototype depends on multiple factors such as materials and procedures and has hence to be discussed in advance.

Our Express Service.

Get in contact now, and your prototype could be a reality in as little as 2 to 3 weeks.