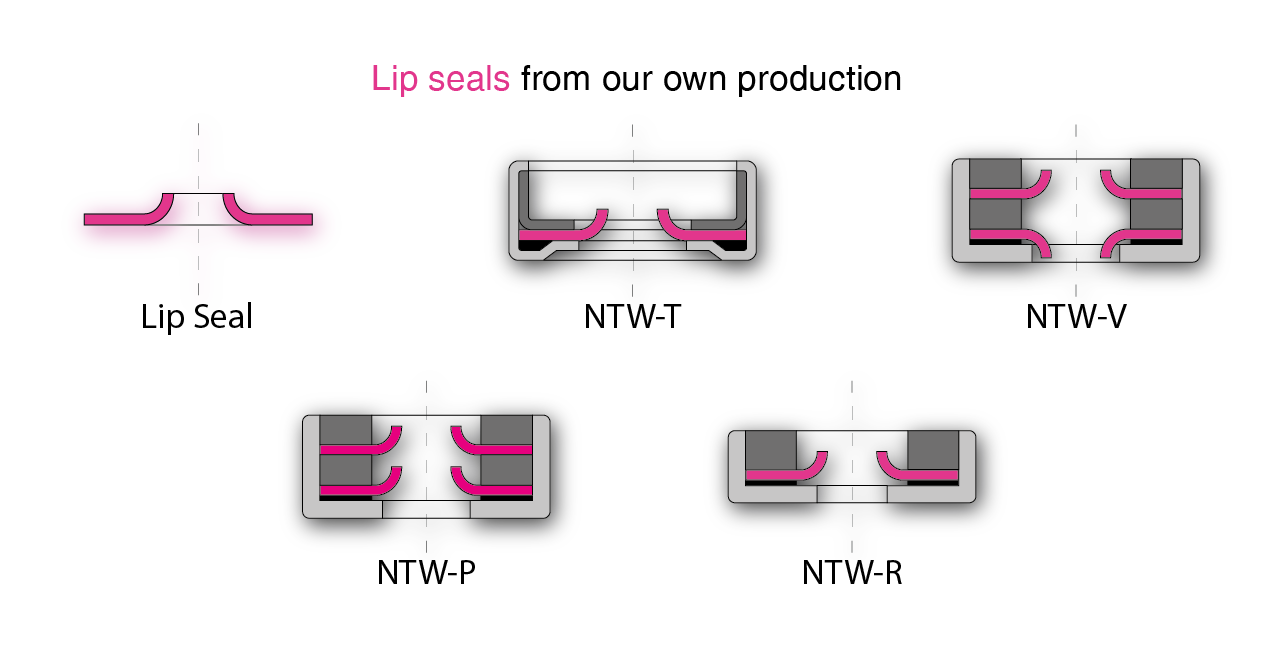

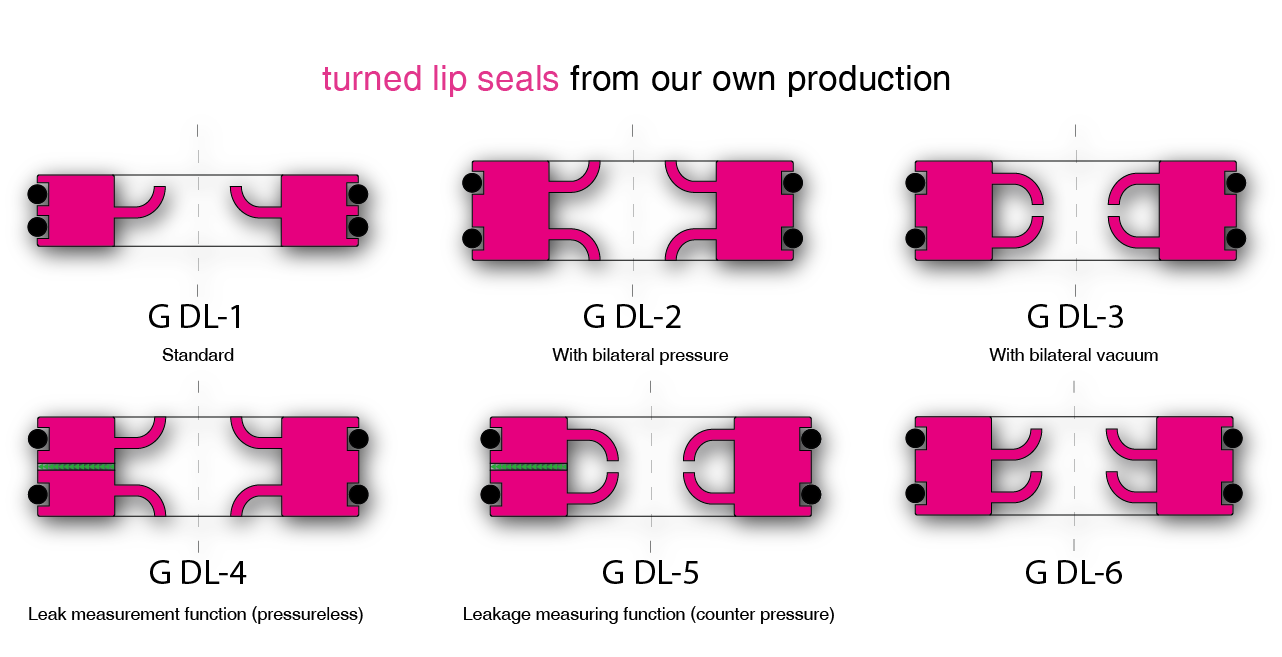

NT Lip seals are reliable rotary shaft seals which find their use in challenging and extreme conditions. They are characterised by good chemical resistance, high temperature resistance and high pressure and load capacity. Our NT Lip Seals have good dry-running properties and can be used at high peripheral speeds. We also have special materials which are best suited for abrasive media.

NT Lip Seals are installed in housings in differing arrangements with intermediate rings, the setup depends on the application and requirements. The whole arrangement is then clamped axially via the press ring.

The shaft hardness must be at least 50 HRC

Operating temperatures

Materialguide

Advantages

- Standard material consisting of special PTFE/graphite components which are self-lubricating.

- Abrasion resistant.

- High chemical resistance.

Disadvantages

- Shaft hardness must be at least 50 HRC.

Advantages

- Material for mechanically demanding applications.

- Long service life with abrasive media and excellent dry-running properties.

Disadvantages

- Not hydrolysis-resistant.

- Lower application temperature range.

- Shaft hardness must be at least 50 HRC

Advantages

- Special material for mechanical, thermal and chemical applications.

- Excellent wear resistance.

- Resistant to continuous thermal stress.

- High creep resistance.

Disadvantages

- Not suitable for applications with alkalis.

- Shaft hardness must be at least 50 HRC.

Advantages

- Excellent chemical resistance.

- Suitable for pharmaceutical and food industries

- FDA approved.

Disadvantages

- Shaft hardness must be at least 50 HRC.

Advantages

- Excellent chemical resistance.

- Suitable for pharmaceutical and food industries

- FDA approved.

Disadvantages

- Prone to cold flow/creep.

- Shaft hardness must be at least 50 HRC.