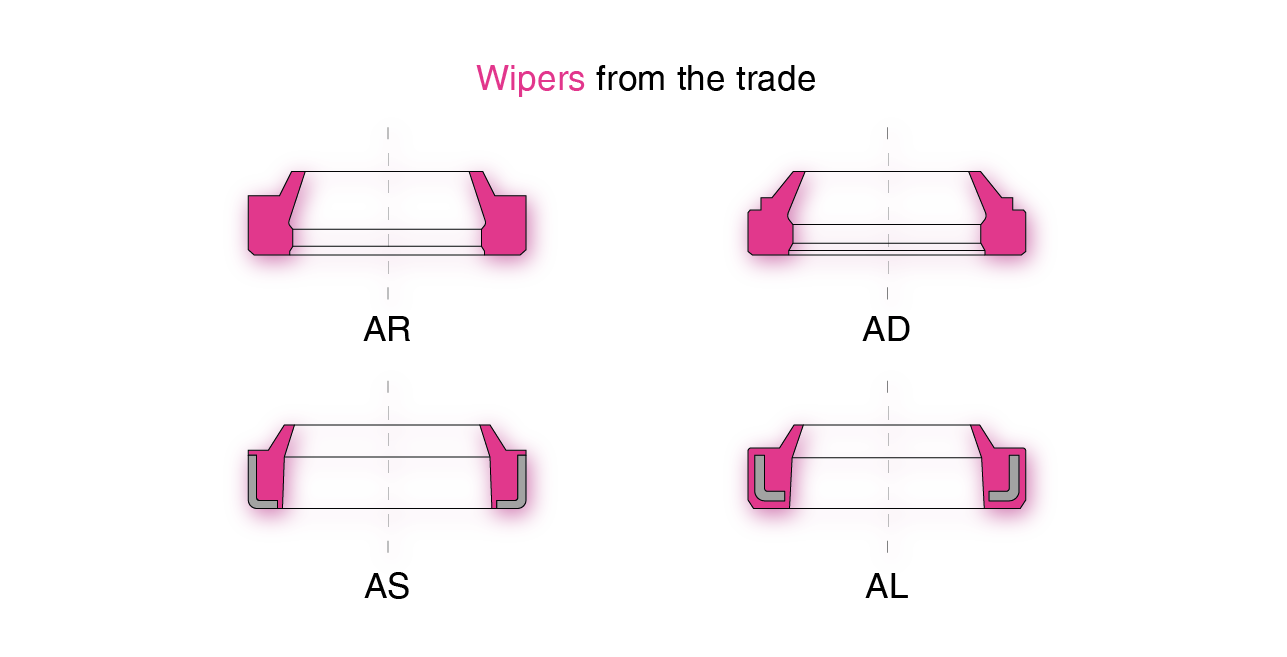

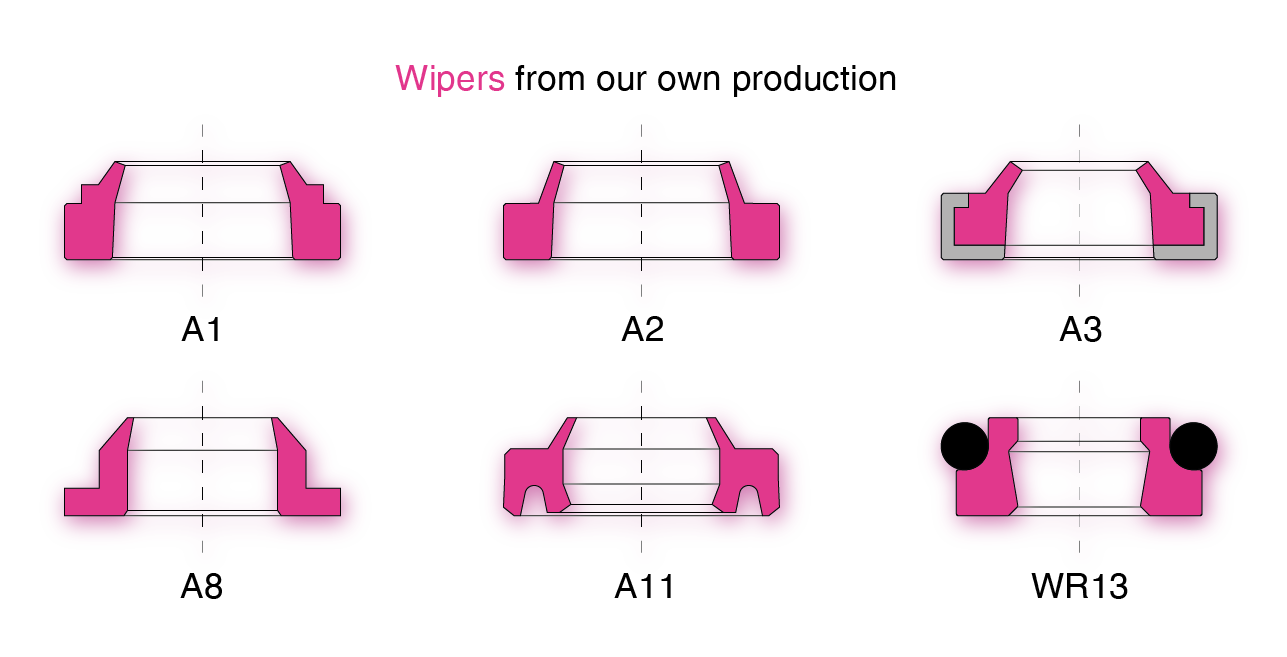

Wipers protect sealing points from dust and dirt contamination. They are vital for the proper functioning of hydraulic units where piston rods retract back into the system.

Wipers do not only protect the seal; the piston rod and spindle would also suffer under the increasing contamination. This reduces efficiency and may even lead to damages where these parts have to be replaced. Wipers hence protect the whole sealed system against grooving and wear.

Abrasion-resistant materials, which are used to manufacture the wipers, guarantee a reliable wiping function and long service life. Wipers often replace bellows and similar dust protection solutions. Depending on the choice of material they are resistant to oils, greases, water petrol and other media

If the standard dimensions do not fit your application we are able to manufacture wipers to your exact specifications and wishes.

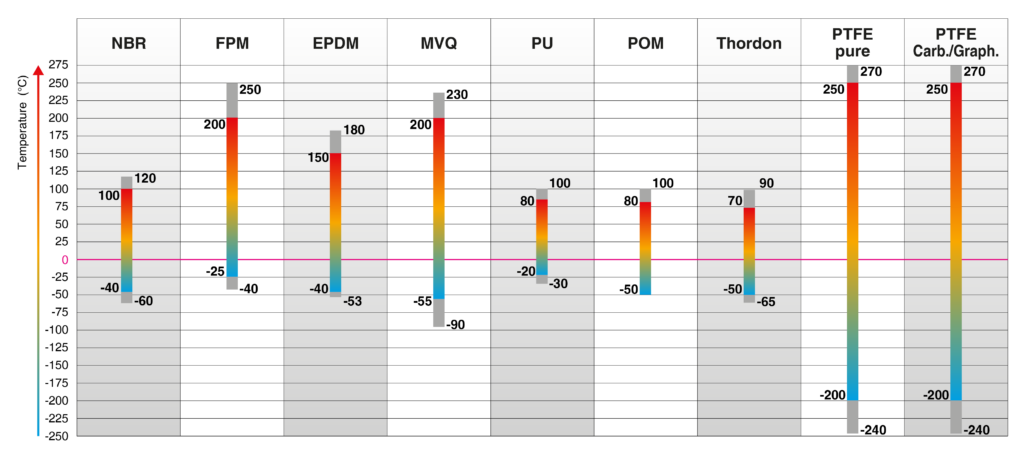

Operating temperatures

Materialguide

Advantages:

- Good swelling resistance to mineral oils, greases and diesel fuels.

- Low gas diffusion.

Disadvantages:

- Insufficient weather and ozone resistance.

- Requires special protective agents.

Advantages:

- Excellent resistance to chemicals and mineral oils.

- High heat resistance.

- Lowest permeability rates for most gases.

Disadvantages:

- Not resistant to polar solvents.

Advantages:

- High resistance to ozone, heat, hot water and alkaline and acidic solutions.

- Resistant to polar solvents.

Disadvantages:

- Not mineral oil resistant.

Advantages:

- Excellent resistance to heat and cold.

- Excellent ozone resistance.

- High electrical resistance.

Disadvantages:

- Low resistance to gas diffusion.

- Average mechanical properties.

Advantages

- Pressure resistant to over 400 bar.

- Hydrolysis resistant.

Disadvantages

- Poorly suited for steam applications.

Advantages

- Good mineral and bio-oil resistance.

- Suitable for applications with alcohol and water up to 90℃

Disadvantages

- Not suitable for applications with steam, air over 100℃ and ozone.

Advantages

- Perfectly suited for abrasive and harsh environments.

- Wear resistant.

Disadvantages

- Low thermal resistances.

- Water absorption.

Advantages

- High chemical resistance.

- Usable for many applications in pharmaceutical and food industries.

- FDA approved.

Disadvantages

- Prone to cold flow/creep.

Advantages

- High chemical resistance.

- Usable for many applications in pharmaceutical and food industries.

- Good thermal conductivity

Disadvantages

- Abrasion particles can be visible as the material is anthracite coloured.