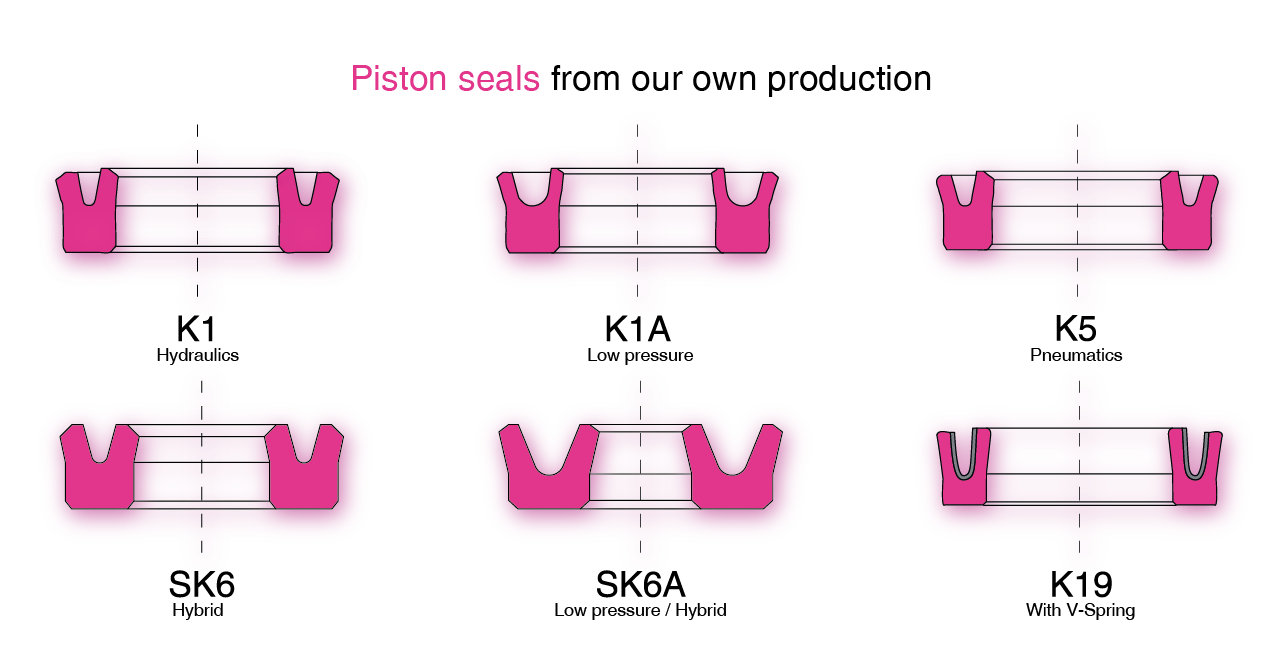

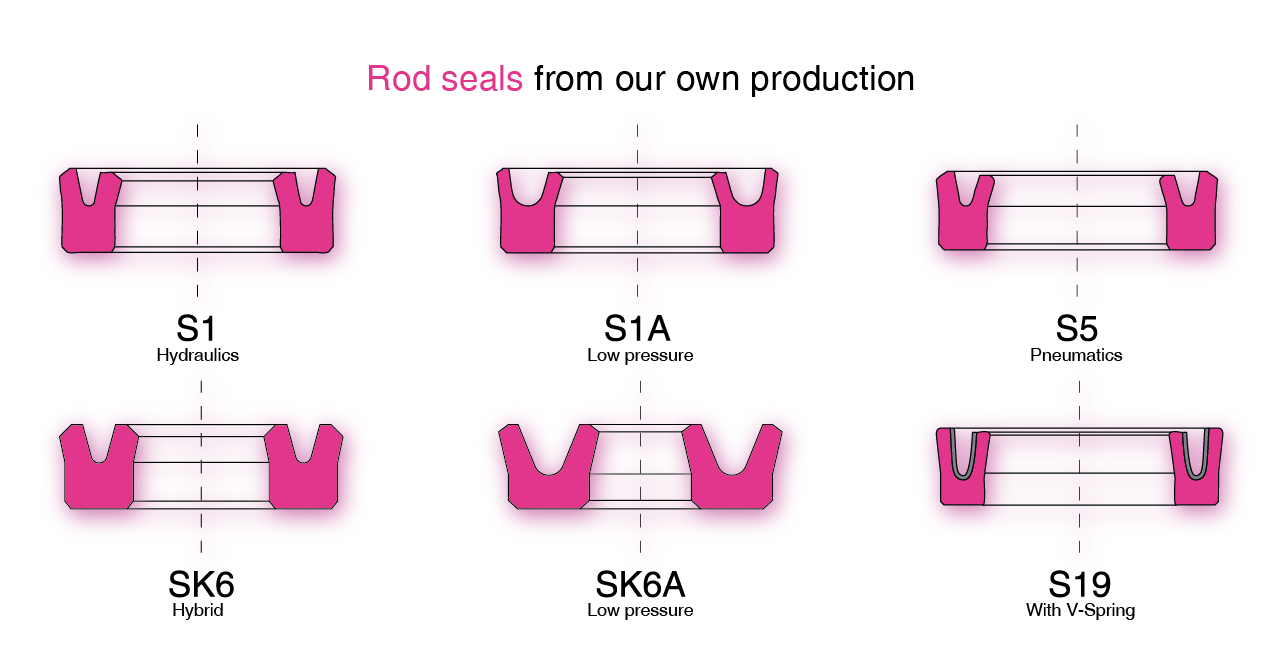

We have an extensive range of commonly used U-Cups on stock in our warehouse and are furthermore able to directly manufacture special designs according to your wishes. The manufacturing service is available in standard or express format.

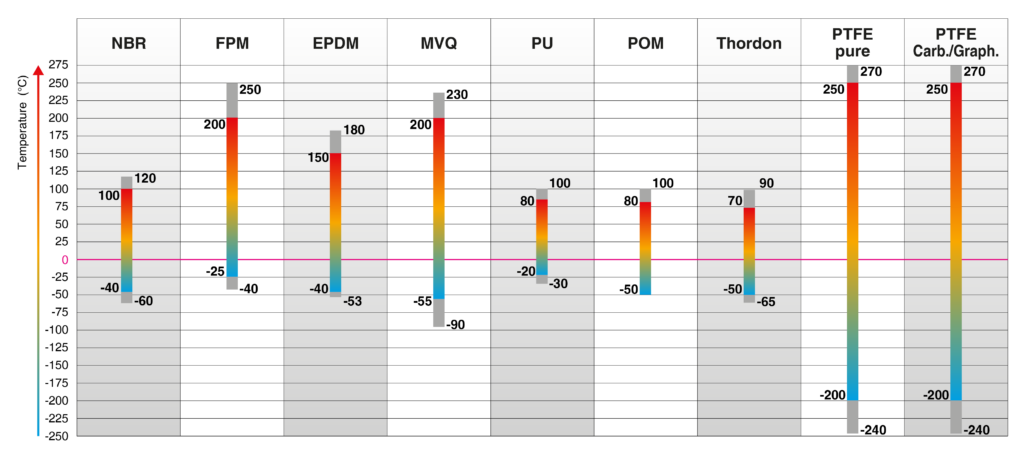

Our U-Cup seals can be used in temperatures ranging from -50℃ up to and including 230℃ and withstand operating pressures of up to 800 bar. Specified properties can be achieved through different cross-sectional shapes, angles and wall strengths. The most important parameters which have to be considered are friction, installation space, maximum pressure, operating temperature and chemical resistance requirements.

In relation to the seals side which is in contact with the moving surface, the U-Cups are classified according to function as either internally or externally sealing. Externally sealing U-Cups are generally cheaper, as the production is faster and less abrasive on the material.

We produce U-Cup seals according to your application requirements in all possible dimensions and standards.

Operating temperatures

Material guide

Advantages

- Good swelling resistance to mineral oils, greases and diesel fuels.

Low gas diffusion.

Disadvantages

- Insufficient weather and ozone resistance.

- Requires special protective agents.

Advantages

- Excellent resistance to chemicals and mineral oils.

- High heat resistance.

- Lowest permeability rates for most gases.

Disadvantages

- Not resistant to polar solvents.

Advantages

- High resistance to ozone, heat, hot water and alkaline and acidic solutions.

- Resistant to polar solvents.

Disadvantages

- Not mineral oil resistant.

Advantages

- Excellent thermal resistances.

- Excellent ozone resistance and high electrical resistance.

Disadvantages

- Low resistance to gas diffusion.

- Average mechanical properties.

Advantages

- Pressure resistant to over 400 bar.

- Hydrolysis resistant.

Disadvantages

- Poorly suited for steam applications.

Advantages

- Good mineral and bio-oil resistance.

- Suitable for applications with alcohol and water up to 90℃

Disadvantages

- Not suitable for applications with steam, air over 100℃ and ozone.

Advantages

- Perfectly suited for abrasive and harsh environments.

- Wear resistant.

Disadvantages

- Low thermal resistances.

- Water absorption.

Advantages

- High chemical resistance.

- Usable for many applications in pharmaceutical and food industries.

- FDA approved.

Disadvantages

- Prone to cold flow/creep.

Advantages

- High chemical resistance.

- Usable for many applications in pharmaceutical and food industries.

- Good thermal conductivity

Disadvantages

- Abrasion particles can be visible as the material is anthracite coloured.